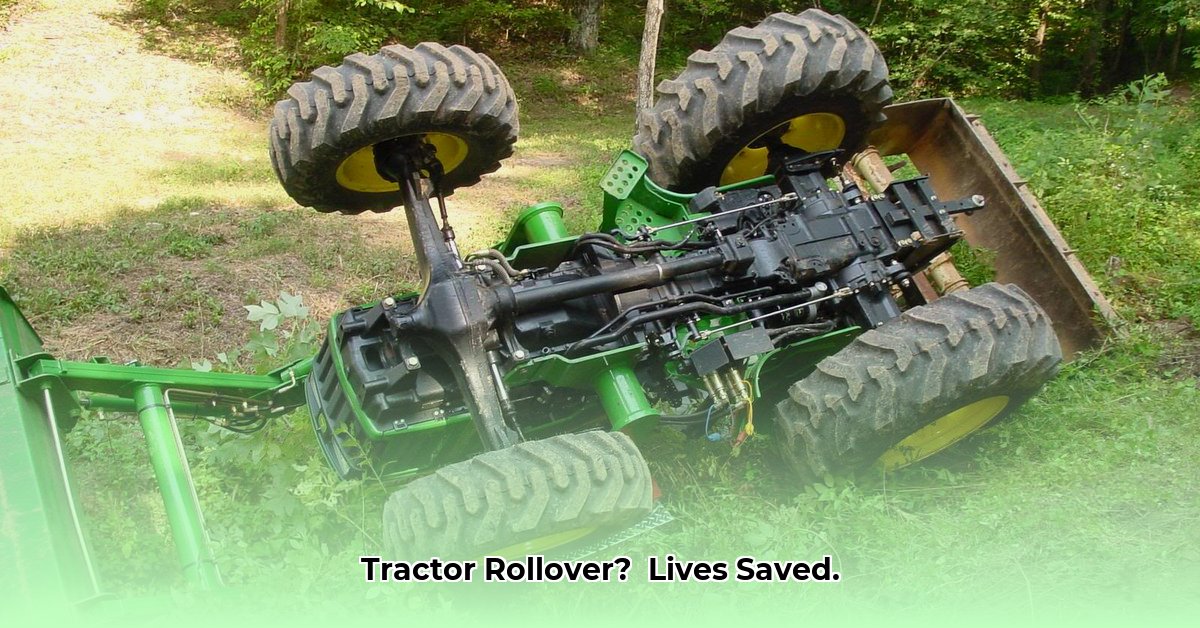

Farming is demanding work, and tractor operation is a significant part of it. However, tractor operation presents considerable risks, with rollovers being a leading cause of serious injury and death among farmers. Investing in a Roll Over Protection System (ROPS) is a critical step toward mitigating these risks. This guide provides essential information and actionable steps to ensure your tractor has a properly functioning ROPS, maximizing your safety and contributing to a more sustainable farming future. For more ROPS information, visit this helpful resource: ROPS safety guide.

Understanding Your Roll Over Protection System (ROPS)

A Roll Over Protection System (ROPS) is a vital safety feature for any tractor. It's a sturdy metal frame designed to protect you should the tractor overturn. Without a properly functioning ROPS, you're at significantly higher risk of serious injury or death in a rollover accident. A ROPS acts as a protective cage, absorbing the impact and preventing the tractor from crushing the operator. Its presence is often mandated by safety regulations, and its absence is a serious liability risk.

Inspecting Your Tractor's ROPS: A Step-by-Step Guide

Regular ROPS inspections are crucial for maintaining its effectiveness and preventing accidents. These inspections should be performed at least yearly, or more frequently in harsh environments. Follow these steps:

Visual Inspection: Carefully examine the entire ROPS structure for cracks, bends, rust, or any signs of wear and tear. Pay close attention to welds and mounting points.

Structural Integrity Check: Assess the overall structural integrity of the ROPS. Check for loose bolts, damaged welds, or signs of weakness. Gently shake the structure to detect any looseness.

Mounting Point Examination: Ensure all mounting points are secure and undamaged. Any play or weakness requires immediate professional attention.

Operational Check (If Applicable): If your ROPS incorporates moving parts, verify smooth, unimpeded operation. Any stiffness or binding indicates a potential problem.

Documentation: Maintain a record of your inspections, including dates, observations, and any necessary repairs. This record will track the ROPS condition and aid in future maintenance.

Retrofitting Older Tractors: Adding a ROPS for Enhanced Safety

Many older tractors lack ROPS. While this doesn’t mean they're inherently unsafe, adding a ROPS dramatically improves safety. However, the retrofitting process can involve costs and challenges.

Cost Implications: Costs vary widely depending on the tractor make and model, the type of ROPS required, and labor costs. You should obtain multiple quotes from qualified professionals.

Finding Qualified Mechanics: It is crucial to seek out experienced farm equipment mechanics certified to install ROPS. A poorly installed ROPS is more hazardous than having none at all. Verify their qualifications and ask for references.

Sourcing ROPS Parts: Contact farm equipment dealerships or online suppliers that specialize in ROPS for your tractor model. Be cautious about using inferior parts for a safety-critical system.

Financial Assistance: Investigate potential financial assistance programs from government agencies or agricultural organizations. Many jurisdictions offer rebates or subsidies to incentivize ROPS installations. These programs can significantly reduce the financial burden.

Choosing a Qualified Installer: Prioritizing Safety Expertise

Selecting a qualified mechanic is paramount. Do not attempt a DIY ROPS installation. A professional ensures proper installation, preventing potential failures and maximizing the ROPS's effectiveness in an accident.

Key Criteria: Choose an installer certified to install ROPS for your tractor's specific make and model. Ask for references and check their experience. A positive word-of-mouth reputation is a valuable indicator.

Maintaining Your ROPS: A Regular Maintenance Schedule

Regular maintenance is vital to prolong the lifespan and effectiveness of your ROPS. Include ROPS inspection as part of your routine tractor maintenance. A yearly inspection should be the minimum, with potentially more frequent checks depending on the environment and usage.

Seatbelts and Other Safety Equipment: A Synergistic Approach

While ROPS offers significant protection, it's only part of the equation. Always wear your seatbelt. This keeps you securely positioned within the ROPS structure, preventing ejection and maximizing the ROPS's protective capabilities. Consider additional safety measures, as appropriate to your farming practices.

Resources and Further Assistance

Numerous resources support farm safety:

- Local Agricultural Extension Offices: Offer valuable information and resources on farm safety practices and local programs.

- Government Agencies: Numerous agencies at state and national levels provide safety guidelines, regulations, and potentially financial assistance.

- Farm Safety Organizations: Several organizations are dedicated to promoting farm safety and offer educational materials and resources.

Cost-Benefit Matrix: ROPS Retrofit

Did you know that a properly installed ROPS can reduce the risk of fatal tractor rollovers by up to 90%? [Source: Insert relevant study or statistic here]

| Feature | Pros | Cons |

|---|---|---|

| ROPS Retrofit | Increased safety, reduced injury/death risk, peace of mind, compliance with regulations | Initial material and installation costs |

| No ROPS Retrofit | Lower initial cost | Significantly higher injury/death risk, non-compliance, potential legal liabilities |

Remember, investing in a ROPS is an investment in the safety and sustainability of your farm and your future. The cost of inaction far outweighs the initial investment. Make safety a priority. Protect yourself, your farm, and your family.